StobbeDPF - all the way from an idea over R&D to a unique product

Porous Re-crystalized Silicon Carbide ceramics for separating particles from hot gases – such as from diesel engine exhaust gases – was all created during the period 1986 to 1994 by Stobbe Tech A/S.

The development work of StobbeDPF (Diesel-Particle-Filter) was financially sponsored by:

- Danish Department of Energy’s Research project from 1987 to 1992. Purpose to develop porous structures intended for diesel particulate filters and hot gas dust filters - 2 mil € budget.

- Danish Department of Industry project from 1991 to 1994. Development of ceramics for hot gas filters - budget >1 mil € combined with FLS-Miljø.

- Per Stobbe’s private pocket.

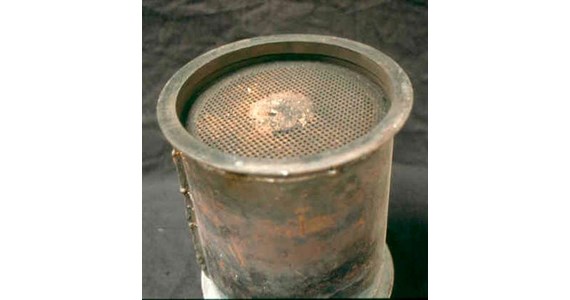

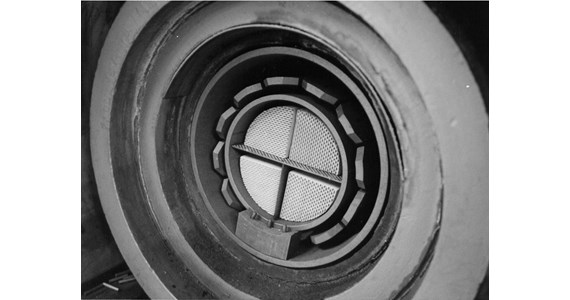

Photo 1: Canned Corning 5.66"x6” DPF app 1985 – Photo 2: Custom spray powdered MA253, extruded and Hydrogen sintered to a world first metal powder DPF tested on a one cyl Hatz diesel on DC dyno app 1986 - photo 3: Extra high 15 gram/liter loaded ReSiC StobbeDPF forced to heavy regeneration – without damages app 1994.

It all started with the shown canned 5.66”×6” Cordierite Wall-Flow-Filter (WFF) tested at Per Stobbe’s final thesis as Mechanical Engineer at DTU (The Danish Technical University) in 1985. It took only one hour on the 3 cyl Buck diesel engine, couple to a Schenk dyno to destroy, melt the center out of the first ever Cordierite WFF in Denmark. This raised the question – how can our international society solve the diesel engine particulate emission problem with WFF based on this fragile material?

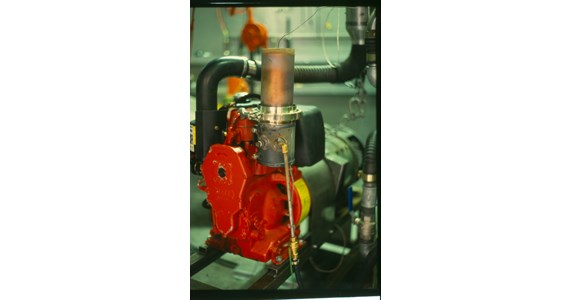

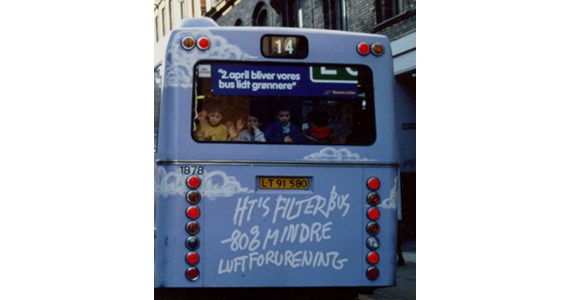

The Copenhagen City Community and City Bus Authorisation requested late 1980ties a DPF technology on buses to improve the air quality in the city. This huge task was given to Stobbe Tech with national funding technically supported by the Danish Technical University.

The remarkable Re-crystalized Silicon Carbide ceramic technology we developed from scratch allowed large, complex dimensions and high porosity structures to be shaped from relatively low-cost coarse grinding SiC grain by extrusion. The extruded bodies dried with only 2% shrinkage and fired at 2500°C with exceptional only 1% shrinkage. Such low shrinkage figures are quite unusual in the ceramics industry. All was developed from scratch - the complete basic science and the manufacturing methods, all the manufacturing equipment such as the complicated extrusion die heads, the wear resistant extruder, the 3 dimensional drying methods / equipment and in particular the challenging design and construction of furnaces capable of operating at 2,500°C in controlled atmosphere.

Processing of segmented DPF 1992 in “The Blue Furnace” by Per Stobbe himself. This remarkable 60 kW furnace was designed entirely by Per Stobbe and build in-house and used for several years to process all ReSiC DPF development.

Over 8 years we were 9 people focusing on developing the bi-modal ceramic method based on cheap SiC grinding powder mixed with an organic binder to shape by extrusion the multi-channel honeycombs. The entire set of production equipment, all the related technologies and even real-life testing on a high number of different vehicles/engines was developed in-house. An impressive achievement for such a small company! At this time, no company had even thought about this principle for “low-cost” manufacturing of thermal stable porous ceramics.

Stobbe Tech A/S received valuable help from:

- Professor Spencer C. Sorenson at Department of Energy Techniques at The Danish Technical University

- Associated professor Jakob Weiland Høj and Associated professor John Emil Engell both from Department of Mineral Industry at The Danish Technical University

- Associated professor Athanasios Konstandopoulos from CPERI in Greece

- Managing Director Richard Utzschneider from Norton GmbH in Bexback, Germany now Saint Gobain Industri Keramik, SGIK in Rödental, Germany

This project and initial work became the fundament for numerous technologies, created many jobs and improved the quality of life for humans in general hereafter. Unfortunately, the technology we developed for DPF purposes was 10 years ahead of its time or the legislation 10 years behind!

The experienced reader will know the Japanese company Ibiden at the same time in parallel developed their quite different mono-modal SiC technology based on the much more expensive finer SiC grain. Further the experienced readers are aware that three different ceramic material technologies later dominated the market for DPF and thus competing:

- Cordierite WFF from Corning and a variety of manufactures - being an oxide ceramic characterized by very low thermal conductivity and thermal expansion

- ReSiC mono-modal technology from Ibiden also manufactured by Saint Gobain SGIK

- ReSiC bi-modal – the Stobbe Tech development - a non-oxide ceramic material characterized by very high thermal conductivity and relative cheap raw materials and manufacturing

The route in the western world to control particle emission from diesel engines has been long and troublesome. The better and more efficient diesel engines the more difficult it becomes to capture and combust the soot, carbon particles. The widely accepted way to reduce particulate emission is by filtering the exhaust gas through typically a high temperature stable Wall-Flow-Filter devise.

Cleaning up exhaust gas from diesel engines is though relatively easy with one of many different sizes of the StobbeDPF. Which has been commercial available since 1992 in 90 (later 200) cell-per-square-inch (CPSI) design ranging from 1 to 40 litre of volume. Later from various suppliers.

A range of segmented DPF in larger sizes we / Notox manufactured early 90ties for a variety of applications. Same product in the 2010ties manufactured by Notox which became Landson. As well as LiqTech A/S and Dinex A/S all Denmark.

Non canned ReSiC 7 segment DPF monolith, 4 segment very early 90ties, 1 segment standard size 90 CPSI. Unique photos from how the first and only black ceramics DPF technology started in the 90ties at Notox.

StobbeDPF electric heated

Electrical regenerated 15 liter DPF

close contact electrical regeneration

Complete DPF package, before assembling and core system integrating the electrical heating. Used for low thermal low diesel engine application in storage facilities not accepting soot dirt

Stobbe Tech A/S developed and patented 1988 the bi-modal ReSiC honeycomb substrate (re-crystalized Silicon Carbide) concept for accurately controlled pore size, porosity and high permeability for capture of diesel engine exhaust particulates. Finally, this turned into the 100% owned daughter company NoTox A/S in 1992.

Manufacturers of the StobbeDPF technology later became:

- dinex.dk - most successful danish manufacturer based on license

- liqtech.dk - aggressive successful company

- NoTox - the factory in Svendborg, Denmark cost 63 mio € to build - now owned by Landson

- ctisa.fr- created a variant of copies without license

- pirelli.com- acquired a license

- Saint-Gobain

You will find extensive information about engine emission at www.dieselnet.com and under research/gas filters on this website.

In Denmark the private bus operator Jesper Blach was ahead of his time as early as 2007. A range of Renault buses with MAN engines in Paris 1992 was equipped with StobbeDPF in 1992. In Toronto year 2000 with Detroit Diesel 2-stroke V6. Volvo and Mercedes in Copenhagen all equipped with custom designed NoTox DPF systems regenerated with fuel additives.

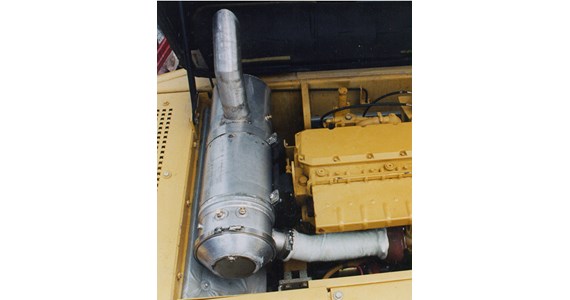

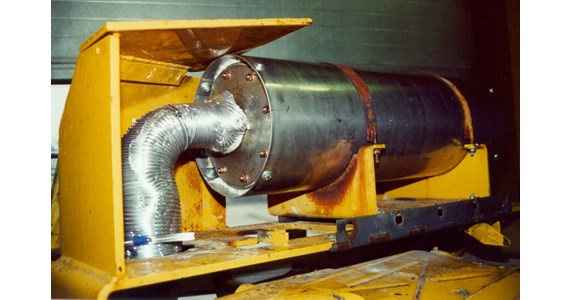

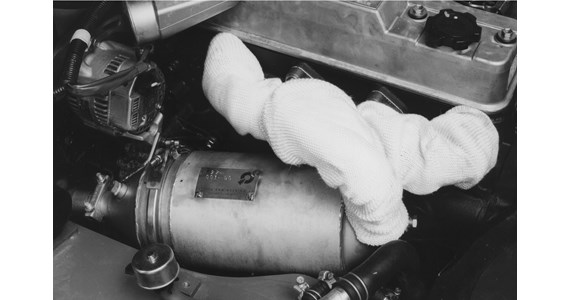

CAT and Liebherr excavators equipped with custom designed StobbeDPF for tunneling use. Kind of advanced as the kit combines DPF, catalyst and muffler within the original muffler space.

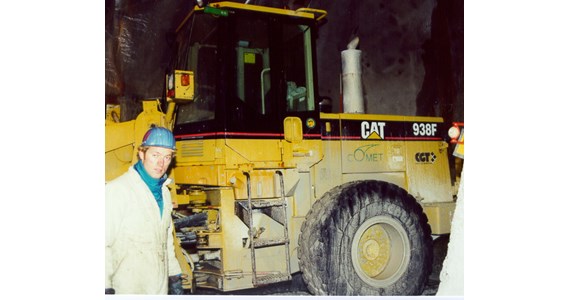

CAT 353 and 973 front loaders equipped with custom designed StobbeDPF for tunnel use in Copenhagen. Kind of advanced as the kit combines both the StobbeDPF, catalyst and muffler all in stainless steel. Some 15 years before any other such provider in Europe. No additives needed!

A unique DPF package for Toyota forklift truck easy to install in 1995. Some 20 years before particles became a daily discussion subject in Europe. Did we know that all the diesel engine manufactures was smart ! yes we knew.

One of many complete DPF packages for different forklift trucks ready to install into the narrow engine compartment. All custom designed by Stobbe Tech and fabricated by daughter company NoTox. Advanced engine modification performed the sequential DPF regeneration. The green forklift truck equipped with dual system integrating electrical heating for off-duty regeneration.

Hundreds of CityCat L-1500 (Rolba, Wetzikon, Switzerland) road sweepers with Mercedes OM 616 4 cyl diesel engine was equipped with combined muffler and catalyst coated dual StobbeDPF operating all over Europe. Improved European city environment significantly for years.

A variety of wheel loaders for indoor use was equipped with DPF and catalysts all over Scandinavia. Improved vastly the metro work in Copenhagen.

- Unfortunately, Per Stobbe 1996 lost all the technology, companies, patents to a hostile raid performed by a range of greedy danish investors, the danish patent agent used for years and two danish banks.

- Corning purchased on commercial condition the NoTox technology package from the "new owners" 1998.

- Two years later Scandinavian Brake Systems (www.SBS.dk) via some other investors obtained the NoTox package from Corning.

- SBS did some really bad management decision, which gave SBS an accumulated financial loss ranging 75 mio € in 2015.

- The two other surviving manufacturing facilities in Denmark was LiqTech and Dinex (DPF production closed 2017).

- Landson purchased 2017 the NoTox assets from the involved banks at 5 m €.

Corning was not part of the bad management, greedy investors in Denmark - Denmark lost 500 jobs.

Per Stobbe - 2017